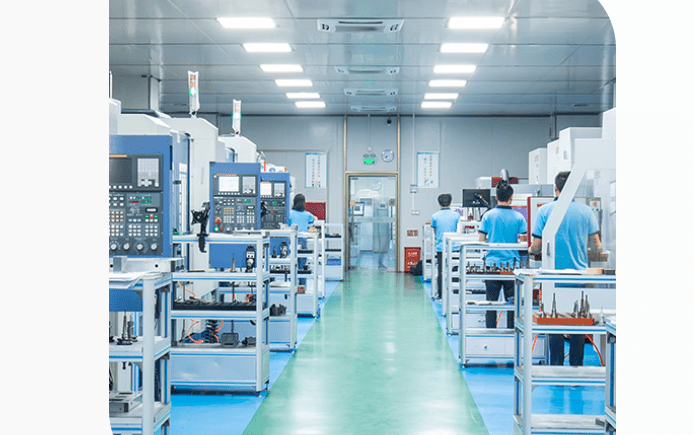

In metal fabrication projects, the design of the product must be spot on. This helps when it comes to your design is interpreted by the fabricators. Engineering drawings are large to a standard, but there can be differences in presentation. Below, we have put together some handy tips to ensure that your metal fabrication project is as streamlined and successful as possible and that you keep your costs to a minimum.

Involve the Fabricator

You might be a brilliant designer and have a superb and exciting idea for a product, but you’re not a fabricator! The art of Would you like to read more about Microsoft Windows-related articles? If so, we invite you to take a look at our other tech topics before you leave! Metal fabrication is enhanced via experience and knowledge. Therefore, you need to talk to your fabricator at the early stages of the design process. What seems right in your mind, and looks good in a 2D drawing, may not transfer into production easily – or indeed at all! However, an experienced fabricator will help make your design feasible, so get them involved in the first instance.

Cut Out the Unnecessary

You want to be specific in both your design and how you present it to the fabricator. Any misunderstanding or confusion will lead to additional time being wasted on correcting things. This can be costly and should not happen if you have involved your fabricator, as we mentioned above. However, mistakes are made, so double-check your designs to ensure that every aspect is easy to interpret.

Use the Right Material

There are many different types of metal, some of which may be suitable for your product. Others will not be suitable, so you need to make sure you choose the right one. The factors involved include strength and weight, machinability – some metals are infinitely harder to handle than others – how the metal can be manipulated, and cost. You probably want to include looks in this too. An expert fabricator will advise you as to the best possible choice of metal for the project and may also help when it comes to getting the right supplier at the right price.

Prototyping and Testing

Sometimes a design looks right and feels right, yet it simply doesn’t work when it reaches its production. This means going back to the drawing board – but you’re not the first and won’t be the last! Ask your fabricator to include pre-production prototypes in the cost of the job, and these should be thoroughly tested to ensure they do the job. If they don’t, you can redesign the problematic aspect without having to shoulder an expensive failure of a manufacturing run.

The above are a few of the things you can do to ensure that your design is optimized for a metal fabrication project, and you will find many more as you become more involved and experienced. Always talk to the fabricator involved. They are familiar with the pitfalls that can be encountered in the production process and help ensure your design is ready for production.

Do you want to speed up your business growth? Do you want your business to experience unusual incremental growth? CamRojud helps many brands achieve this goal, and we publish regular contents that offer advice about making the transition.

Would you like to read more about metal fabrication-related articles? If so, we invite you to take a look at our other tech topics before you leave!